Series MC ceramic slurry pump

Series MC ceramic slurry pump

Series MC anti-wear ceramic pump is based on slurry pump, taking advantage of the advantages of anti-corrosive and anti-wear of ceramic materials, a new generation of ceramic slurry is developed by combining the technological characteristics of ceramic materials slurry pump. The product has the advantages of simple structure, good interchangeability and high universality. Once launched, it has been praised by customers.

View Detail Series MD ceramic slurry pump

Series MD ceramic slurry pump

Series MD ceramic slurry pump is an improved ceramic slurry pump based on the traditional single slurry pump casing. It has the advantage of simple structure of single pump casing. At the same time, it has the characteristics of anti-wear 、 anti-corrosive and anti-impact . Widely used in mine, metallurgy, electric power and other industries to transport wear and corrosion liquids.

View Detail Slurry pump spare parts ceramization

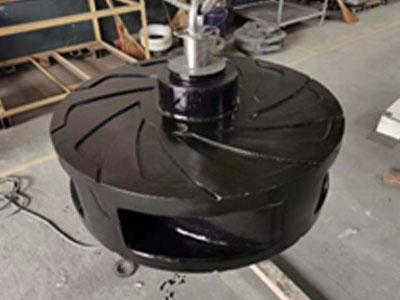

Slurry pump spare parts ceramization

Slurry pump spare parts ceramization:12/10ST-AH Impeller、80ZJ-I-A42 Impeller、150ZJ-I-A60 Impeller\Liner 、80ZJ-I-A42 Liner、Slurry pump liner、Slurry pump suction discharge liner tube

View Detail Series LCF ceramic desulfurization pump

Series LCF ceramic desulfurization pump

Series LC ceramic desulfurizer pump is based on common dual-phase steel metal desulfurizer pump , combined with the characteristics of ceramic anti-wear and anti-corrosive ,especially in the work condition of high chloride ion wastewater, a new generation of ceramic desulfurization pump is designed and developed . Anti-wear and anti-corrosive ,easy maintenance, good interchangeability , It is an ideal product for conveying slurry in desulfurization and chemical engineering as well as smelter.

View Detail Series LCC ceramic desulfurization pump

Series LCC ceramic desulfurization pump

Series LCC ceramic pump is based on LC slurry circulating pump , according to the technical parameters and structural characteristics of large ceramic pump ,Combined with ceramic technology and mold economy as one, and the development of a new generation of high efficiency desulfurization circulation pump for large desulfurization tower slurry circulation transportation .

View Detail Series LCC desulfurization pump parts ceramization

Series LCC desulfurization pump parts ceramization

Series LCC desulfurization pump parts ceramization:800DT-A90 Pump casing、LC600-825 Impeller、600X-TLR Suction cover、700DT-A90 Rear liner、LC100-350-B4 Impeller、PLC100-300 Pump casing、LC125-405 Pump casing、LC80-400 Impeller、LC65-310 Cover (wear plate)、LC125-405 Part restore、Pump casing 3D design

View Detail-

BEST QUALITY

BOCO Construction Services are committed to meeting the highest quality standards without compromising our safety culture..

-

ON TIME

At our company, we respect the customer’s time and schedule and always complete the projects on timely fashion way.

-

CUSTOMIZED PUMP

As the saying goes practice makes perfect. With our years of experience you can bet on us to get the job done exactly to your specifications.

Hebei Boco Pump new Material Co., Limited is a comprehensive enterprise integrating research and development, manufacturing, sales and service. Products are widely used in metallurgy, mine, chemical industry electric power, building materials etc. It is used to transport wear and corrosive liquids. Business scope:Pump technology development and promotion、Research and development of new materials ;Mechanical equipment、Pump and spare parts production, sales and services . In order to meet different industrial needs, the company can provide ceramic slurry pumps and spare parts, ceramic desulfurization pumps and spare parts, as well as anti-wear and anti-corrosion solutions for industrial enterprises. The company has always attached importance to technological innovation, energy conservation and environmental protection. Insist on putting the needs of customers first place.

READ MOREThe centrifugal slurry pump is the most common slurry flow pump used in mining industries. ....

A pump is a machine used to transport liquids or pressurize liquids.....

Possible faults and Solutions for the Pumps....

In order to ensure the safe operation of the pump,please pay attention to the following aspects for maintenance.....